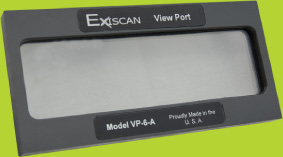

XIR Infrared Windows From ExiscanTM

![]()

|

|

Why ExiscanTM ?

|

XIR Infrared Windows From ExiscanTM

![]()

|

|

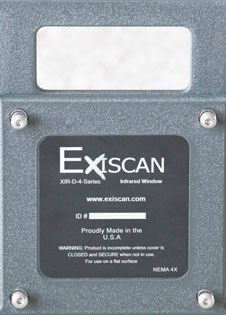

XIR Specifications

*Standard Cover Screw Type: Allen Head (5/32” Hex Socket). Other options available.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

XIR Infrared Windows From ExiscanTM

![]()

|

|

Quick & Easy Installation XIR infrared Windows require a one-time modification to the enclosure. A qualified person will use a knock-out punch or saw to cuts the appropriate sized aperture and drills eight pilot holes in the panel or door. A team of two technicians can install five to eight windows an hour if properly equipped.

Installation Instruction and Templates: Installation instructions and a sticker-backed template are included in the packaging with each window shipped. View installation instructions, installation templates and engineering drawings for mounting here.

Installation Tools: The rectangular opening gives users the latitude to either use a knockout punch, saw, cutoff wheel or nibbler when installing the XIR Series IR windows. View more information about recommended installation tools here.

|

Page 2 of 2